Case Study

Lynemouth Minewater Treatment Baffles

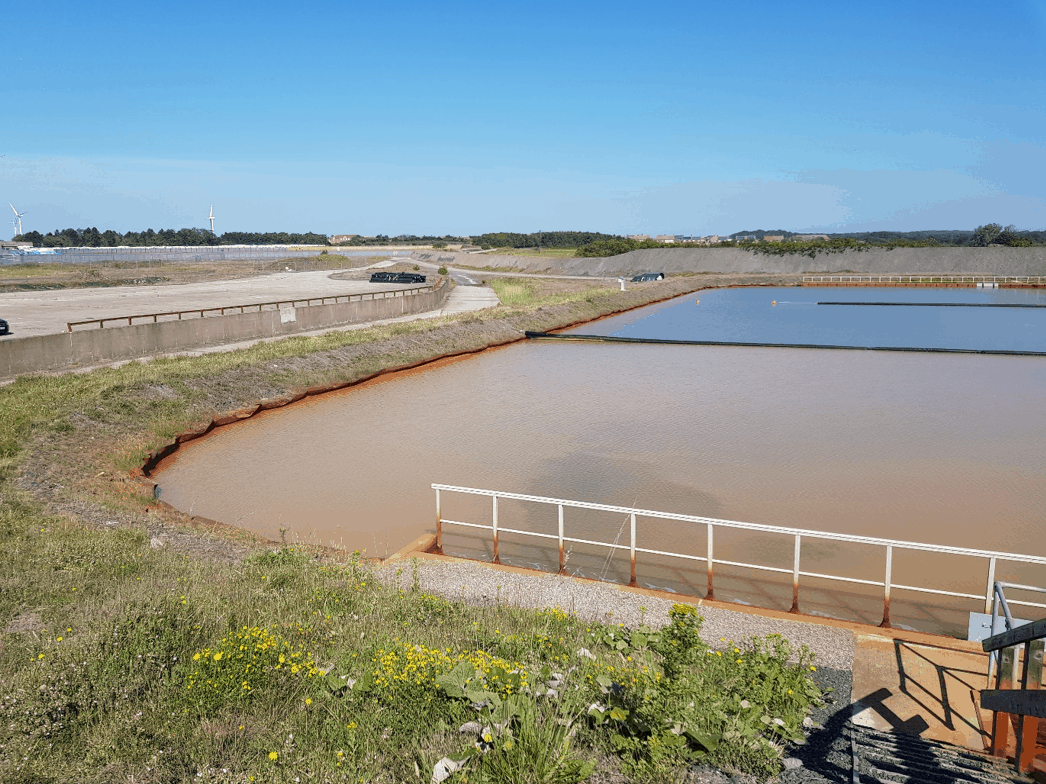

The Lynemouth Phase I Mine Water Treatment Scheme (MWTS), is located on the Northumberland coast on the site of the former Ellington Colliery.

Water

Treatment

Coal mine water is extracted at a rate of approximately 85 Litres per second from an abandoned mine shaft and treated through two lagoons, configured in a series before the cleaned water is discharged into the sea. The lagoons are constructed in colliery spoil and lined with a High Density Polyethylene (HDPE) liner.

The treatment process is designed to reduce the total iron in the effluent which displays as ochre sludge in the lagoons; the mine water being subject to peroxide dosing. The lagoons are taken offline periodically in 24 month intervals, to enable the removal of the sludge by means of pumping.

Challenges &

Solutions

The Coal Authority required a pair of bespoke baffles in one of the lagoons located at Lynemouth Mine Water Treatment Scheme. John F Hunt designed, manufactured and installed the baffles to optimise the existing treatment process by:

- Increasing the time in which the effluent spent in the lagoon

- Improving the longitudinal mixing characteristics

- Optimising the reaction and settlement of ochre within the lagoon

Alongside our chosen contractor, we also provided an engineered foundation solution for mounting the baffle stanchions and fitted the two adjustable devices across the lagoon. A total of fourteen 2050mm ground screws were used, which quickly, accurately and safely secured the baffles to their customised stanchion base plate system.

The entire project was installed, tested and completed within one week.