Case Study

Wheal Jane

Long term operation and maintenance of flag ship mine water treatment scheme.

Location &

Overview

The Coal Authority on behalf of DEFRA and the Environment Agency awarded the operation and maintenance contract for the Wheal Jane mine water treatment scheme near Truro, Cornwall to John F Hunt Regeneration in 2021.

The contract to manage the Mine Water Treatment Plant (MWTP) lasts for 5 years, with an option to extend for a further 5 years.

Background

Information

The Wheal Jane MWTP was built after a catastrophic release of contaminated water in 1992, a year after the mine was closed and its pumps turned off. A drainage tunnel, or adit, near the surface collapsed and more than 50 million litres of acidic mine water poured into the Carnon River and the Fal Estuary. This was the biggest water related pollution incident in the UK and ranks highly among the world’s largest water pollution events.

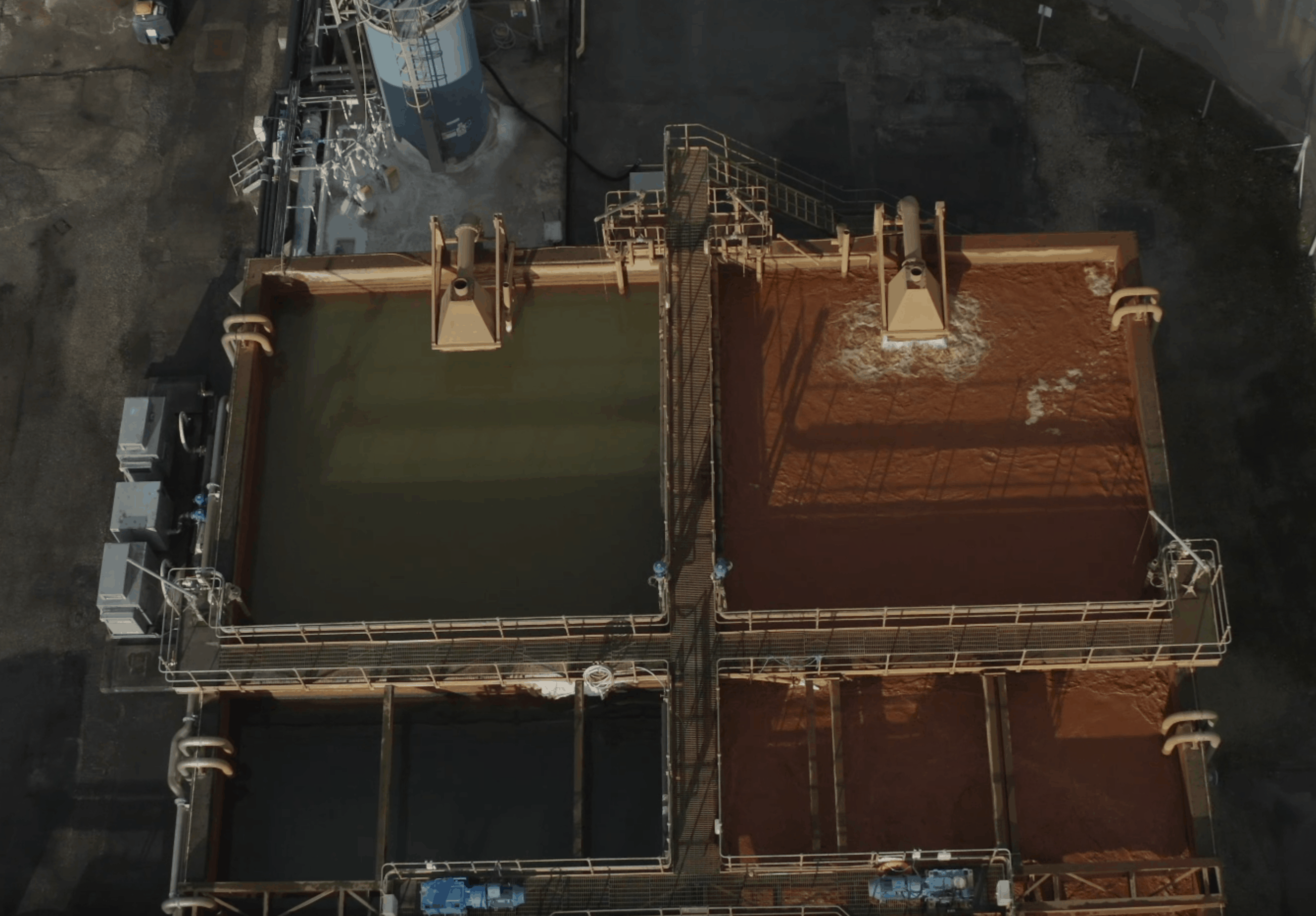

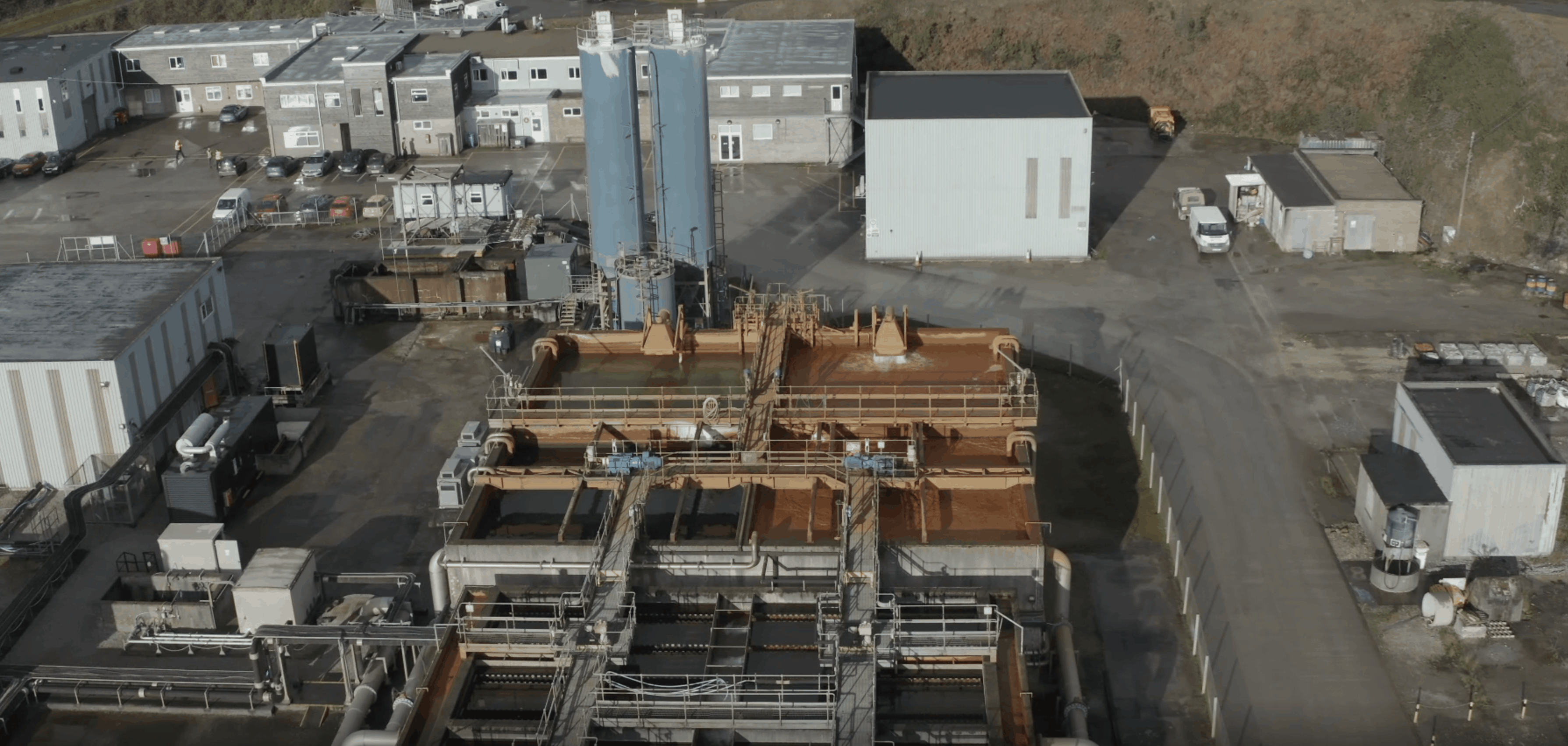

The Wheal Jane Scheme treats mine water abstracted from below ground, and uses a high density sludge process to remove metal from the mine water.

The resultant sludge is pumped to a dam and the treated water is discharged to a stream. In a typical year approximately 6,000,000 m³ of mine water is treated, with 600 tonnes of metal contaminants (predominately iron and zinc) removed. The process requires about 2,000 tonnes of hydrated lime, 7,000kg of anionic flocculant and 3,000 MW-h of power annually.

In addition to the operating plant, the plant infrastructure includes a workshop, storage facilities and office space. Wheal Jane mine water treatment scheme

Services

Provided

John F Hunt ensure the effective and continuous operation of the plant 24/7, 365 days per year. To enable this requires a dedicated team of engineers to:

- Conduct daily checks on the plant, take samples and carry out maintenance activities;

- Make informed adjustments to the treatment process to ensure efficient use of chemicals and power;

- Procure chemicals and supervise delivery;

- Develop and implement an asset management programme and budgeted Construction Plan to maintain / improve plant performance;

- Ensure compliance with consents, licenses and permits and liaise with appropriate regulatory bodies;

- Adhere to health, safety and environmental standards;

- Report operational costs, safety statistics and performance trends;

- Provide and manage an operational database to capture and store critical plant data;

- Project manage capital improvement schemes to the plant;

- Improve and maintain emergency procedures.

Additional services that may be instructed include:

- Managing, supervising and assisting in research and development projects;

- Providing flow monitoring and water sampling services to adjacent sites in the southwest region.